-

МОБИЛЬНЫЕ ТЕЛЕФОНЫ+86 13376920836

МОБИЛЬНЫЕ ТЕЛЕФОНЫ+86 13376920836 -

ПОЧТОВЫЙ ЯЩИКsales@cxplc.com

ПОЧТОВЫЙ ЯЩИКsales@cxplc.com

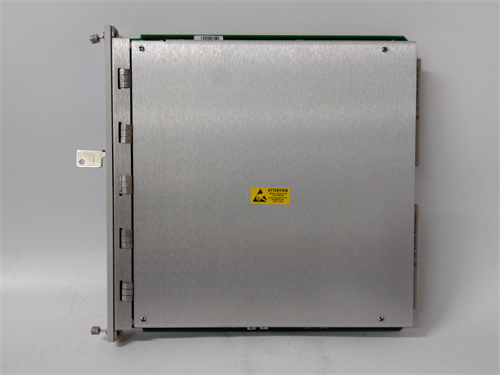

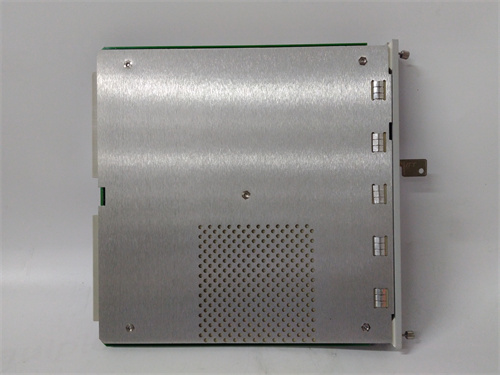

BENTLY 3500/20

The BENTLY 3500/20 is a versatile and robust vibration monitoring module designed for asset protection and condition monitoring of rotating machinery. This module is a part of the BENTLY 3500 series, which is renowned for its superior performance and reliability. The 3500/20 specifically focuses on providing advanced vibration analysis capabilities, ensuring that your machinery operates safely and efficiently. It facilitates real-time monitoring and diagnostic functionality critical for predictive maintenance.

The BENTLY 3500/20 offers numerous advantages, including:

The BENTLY 3500/20 is commonly used across various industries, including:

One notable case study involves a petrochemical facility that implemented the BENTLY 3500/20 for monitoring their compressor systems, resulting in a 30% improvement in maintenance scheduling and a significant reduction in unplanned downtime.

When comparing the BENTLY 3500/20 with other vibration monitoring solutions, such as the Siemens SINAMICS series and the Emerson CSI series, several strengths stand out:

When selecting the BENTLY 3500/20, consider your specific application needs, including the type of machinery you are monitoring and the environmental conditions of your operational site. Ensure compatibility with existing systems and evaluate the need for future scalability.

It is essential to properly configure the BENTLY 3500/20 according to the manufacturer's guidelines to avoid any inaccuracies in the measurements. Regular calibration and maintenance are recommended to ensure the module's performance remains optimal.

We are your trusted partner, providing sales and technical support for the BENTLY 3500/20 and other automation spare parts. Enjoy special discounted prices by contacting us; we are here to serve you.

Предыдущая статья :

BENTLY 135489-03Следующий пост :

CI801 3BSE022366R1